Barhale completes foul and surface water sewer connections on behalf of Yorkshire Water

11th August 2020 Barhale’s successful completion of more than 1.6km of new foul and surface water sewers in Chesterfield clears the way for the construction of 250 new Taylor Wimpey homes in the Derbyshire town.

Barhale’s successful completion of more than 1.6km of new foul and surface water sewers in Chesterfield clears the way for the construction of 250 new Taylor Wimpey homes in the Derbyshire town.

The end of the project marks the fulfilment of a 20-month contract on behalf of Yorkshire Water.

The site at Derby Road had been the location of the former Avenue Coking Works. While it had recently been remediated and transformed into public open space and building land, the Barhale team needed to plan and manage operations carefully to take into account possible ground contamination.

An initial design solution had proposed to install a gravity pipe system into Yorkshire Water’s existing foul sewer. Connection would have been made beneath the floodplain of a newly constructed dam constructed to protect Chesterfield from flooding. However, the proposed route required passing through land adjacent to the River Rother, contaminated by the historic coking industry.

A collaborative approach between Barhale, Yorkshire Water, the Environment Agency and Jacobs/GHD designers was able to identify an alternative route which, while slightly longer, minimised the need to excavate in contaminated land and avoided crossing the river.

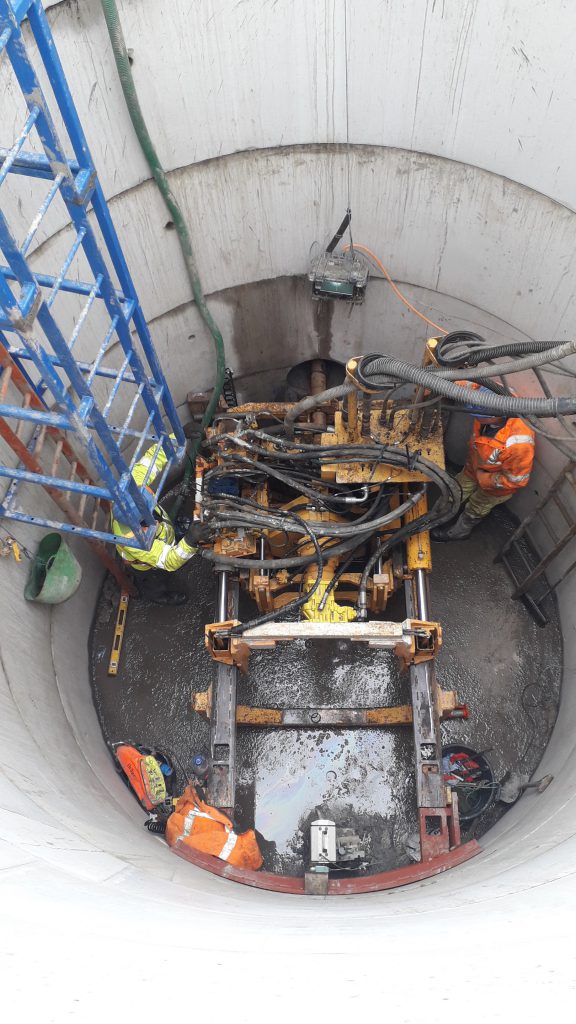

Barhale started work in November 2019. Traditional open cut trench excavation was used to lay the new sewers in the adjacent inert farm and sports land. Augerbore No-Dig techniques were employed where trenches would have been too deep and where the ground had been remediated – to mitigate risk to the site team.

Constructed mainly in 300mm and 150 diameter clay pipework, 950m of foul water and 700m of surface water sewers were connected to the Yorkshire Water network. Twenty (no.) new manholes have been installed.

Barhale’s project manager Michael Healey described the challenge.

“This is a great location but historically it was at the heart of Chesterfield’s coking industry – and that left a legacy,” he said. “We were undoubtedly aided by the fact that the ground had recently been remediated but we needed to be mindful and, as is our standard operating practice, we conducted full risk assessments throughout the project to ensure that we met any issues safely and appropriately.”

“The new route meant that we were excavating less in the remediated ground and were not having to cross the river Rother. It also kept our work outside of the dam’s floodplain – in what turned out to be one of the wettest winters on record.”

“We are really pleased that despite encountering many challenges Barhale and our partners have designed and delivered a successful project for Yorkshire Water without incident.”